Design pharmaceutical facilities in minutes.

The first simulation tool built specifically for GMP cleanrooms. Validate zoning, optimize flows, and estimate HVAC loads with engineering precision.

Validation Status

ISO 14644 Compliant

Trusted by engineering teams at

Stop designing by intuition.

Pharma facilities are too complex for intuition. Changes late in the project cost up to 15x more. Our tool replaces manual spreadsheets and assumptions with science-based simulation.

Compliance Risk

Cleanroom zoning rules are increasingly strict. One error can delay validation by months.

Hidden HVAC Costs

HVAC represents 40–70% of energy costs. Oversizing is wasteful; undersizing is fatal.

Slow Feasibility

Manual feasibility studies take 4-8 weeks. You need answers in days, not months.

From concept to compliance.

Accelerate your design process with a streamlined workflow.

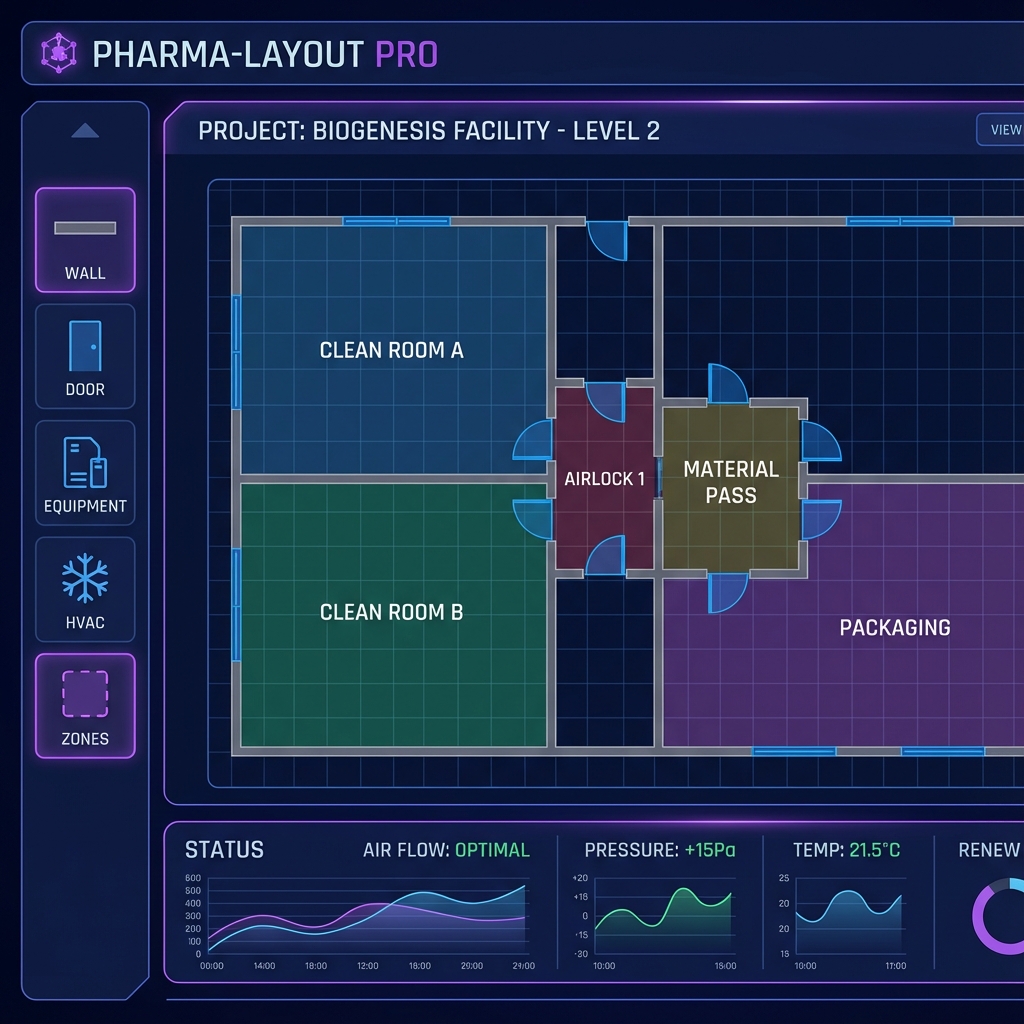

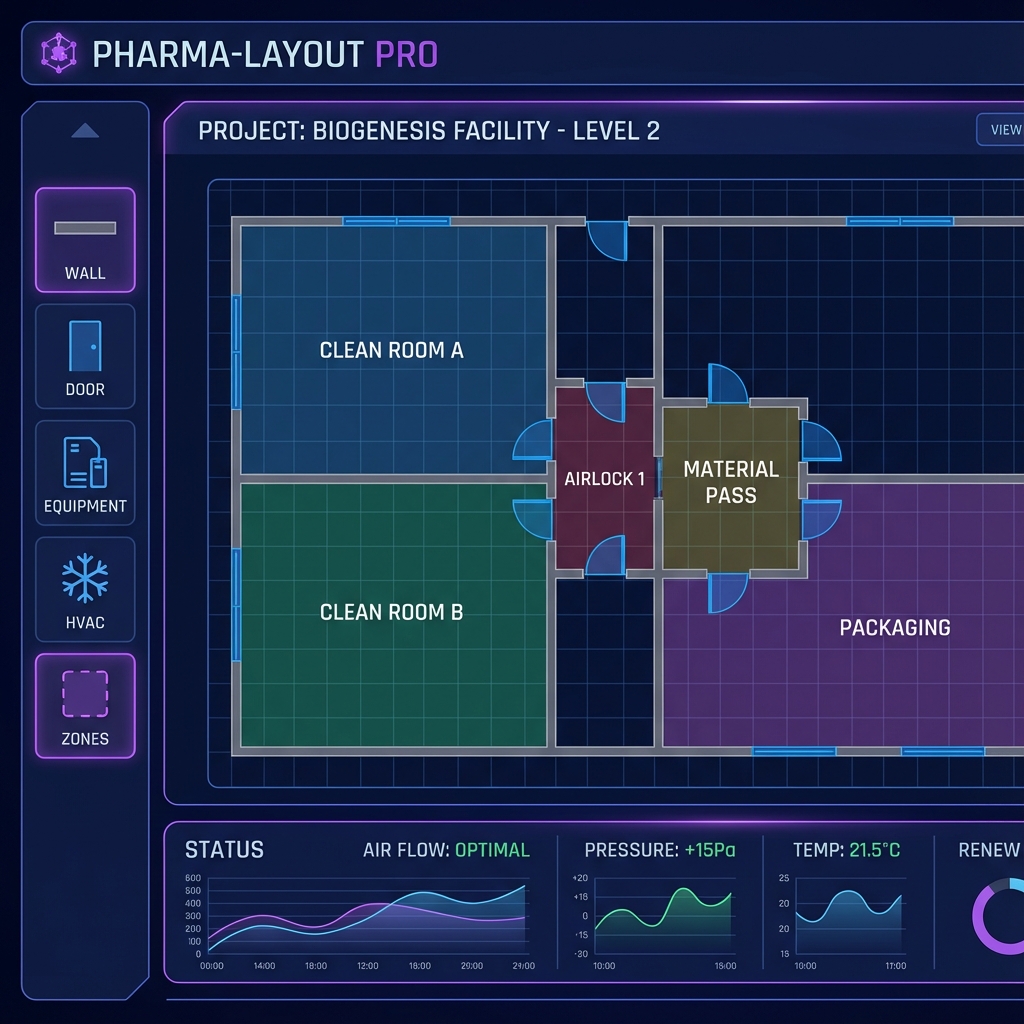

Layout

Draw rooms & airlocks with intelligent snapping.

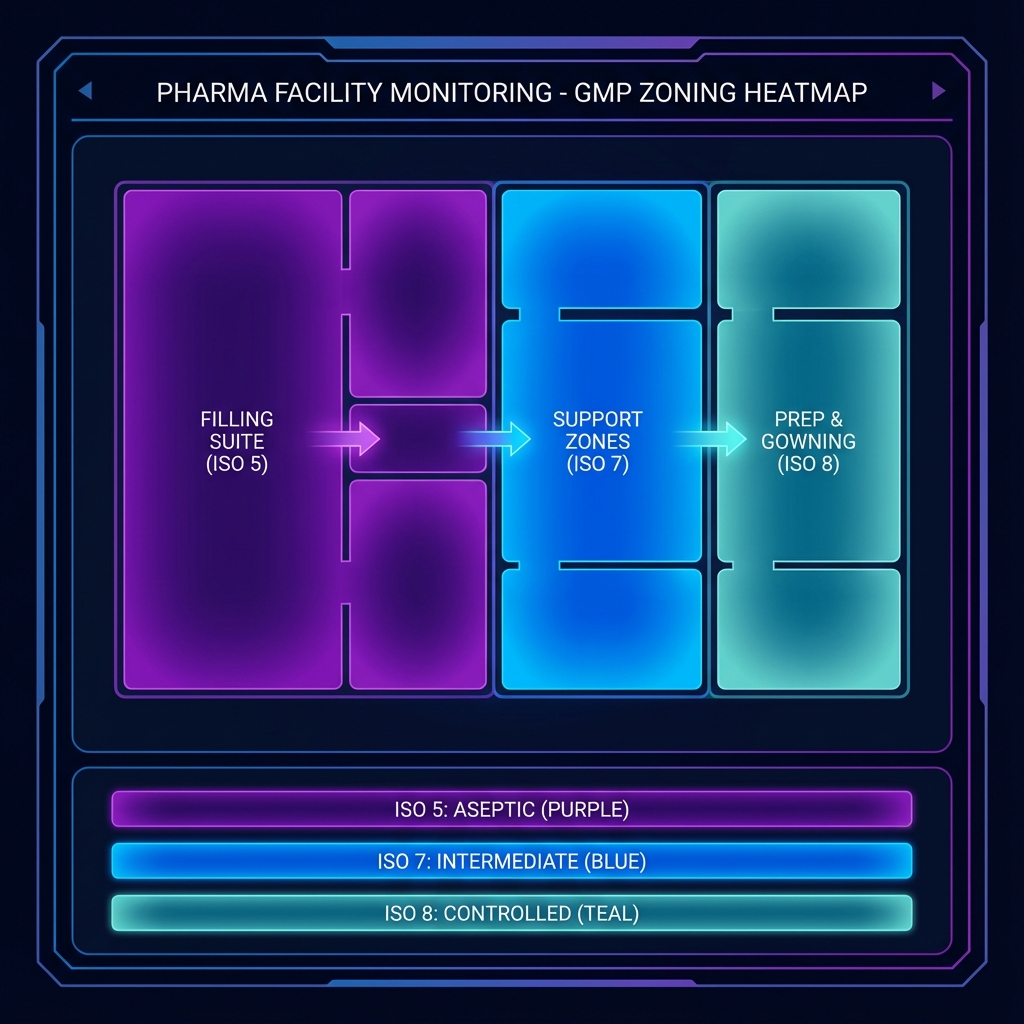

Zoning

Auto-assign ISO classes (5/7/8) and pressure cascades.

HVAC

Instant calculation of airflow, ACH, and thermal loads.

Simulation

Detect personnel & material flow conflicts automatically.

Report

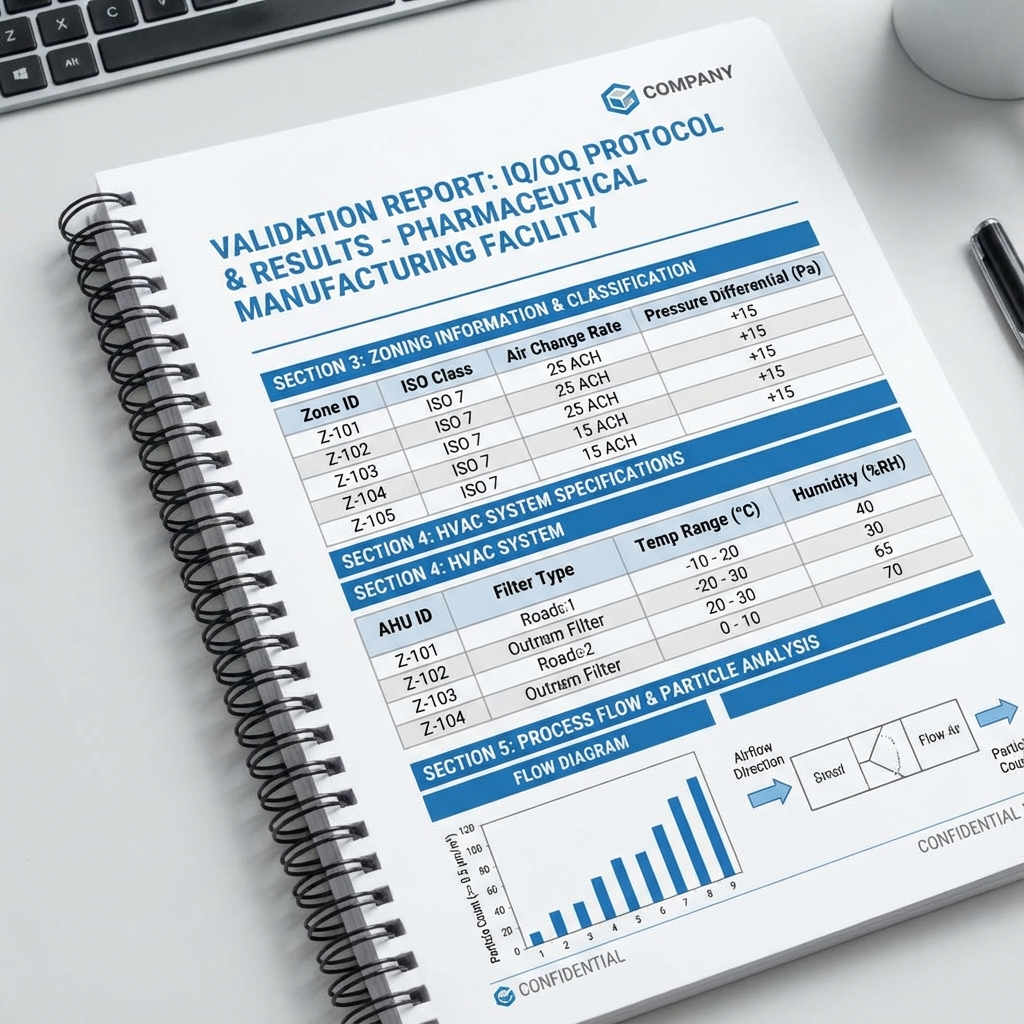

Export pre-IQ/OQ documentation instantly.

Engineered for the Industry

Not a generic CAD tool. Every feature is designed with GMP guidelines and cleanroom physics in mind.

ISO Class Engine

Automatic classification based on process type.

Pressure Cascades

Visual verification of differential pressures across zones.

Load Calculator

Early-stage estimation of cooling and heating requirements.

Contamination Analysis

Highlight crossing paths between clean and dirty flows.

Audit-Ready Docs

Generate PDFs that serve as the foundation for IQ/OQ.

Scenario Compare

Test multiple layouts side-by-side to find the optimal design.

Frequently Asked Questions

Ready to modernize your facility design?

Join the leading CDMOs and engineering firms using PharmaTwin.